Rotary evaporators are essential tools in modern labs, routinely used to recover solvents, concentrate solutions, and isolate compounds. Traditionally, researchers set up their rotovaps inside a chemical fume hood to manage hazardous vapors.

But while a fume hood does provide some protection, it isn’t always the best fit for rotary evaporation. Their vertical clearance can limit the use of tall condensers, and frequent sash adjustments interrupt airflow patterns. These small frustrations can add up, reducing both safety and convenience.

That’s where dedicated rotary evaporator enclosures come in. Designed specifically around the unique geometry and operation of a rotovap, these enclosures provide reliable containment while offering better ergonomics, visibility, and flexibility than a standard fume hood.

The Hazards of Rotary Evaporation

Even when properly assembled, a rotary evaporator carries risks that demand thoughtful containment:

- Vapor release. Volatile solvents can escape during setup, pressure changes, or flask removal, potentially exposing lab personnel to harmful fumes.

- Glassware failure. Flaws in glass, sudden vacuum changes, or thermal stresses can cause catastrophic failures. If it happens, sharp fragments and chemical splashes can cause serious injury.

- Operational challenges. Rotovaps often require tall condensers or diagonal setups that can be awkward inside a fume hood, leading to workarounds that compromise safety.

These risks don’t mean rotovaps are unsafe to use — only that the right control measures are critical to keeping researchers protected.

Why Fume Hoods Aren’t Always Enough

Fume hoods remain the default control device in many labs, and for good reason: they provide effective airflow that helps capture hazardous vapors. But when it comes to rotary evaporators, they present several limitations:

- Space constraints. Tall glassware and condensers often don’t fit comfortably in standard hoods.

- Shared use. Fume hoods are valuable real estate, frequently occupied by multiple pieces of equipment or experiments.

- Interrupted airflow. Raising and lowering the sash to make adjustments can disrupt containment efficiency.

- Visibility. Deep workspaces and glass panels can make monitoring your setup more difficult than it should be.

In short, fume hoods simply weren’t built with rotary evaporation in mind.

The Advantages of Rotary Evaporator Enclosures

Rotovap enclosures are engineered specifically to overcome these limitations. Key advantages include:

- Optimized dimensions. Enclosures provide extra internal height and workspace, making it easier to accommodate large condensers and angled setups.

- Clear visibility. Transparent sides and front access doors ensure researchers can monitor processes without compromising containment.

- Consistent airflow. Purpose-designed intake slots and airflow patterns maintain protection even during adjustments.

- Safer barrier. In the rare event of glassware failure, the enclosure serves as a physical shield between the operator and the equipment.

- Dedicated use. A rotovap enclosure reserves a defined space for one critical task, freeing up fume hoods for other applications.

Compliance and Best Practices

It’s not just a matter of preference. Laboratory safety standards reinforce the need for effective vapor containment. OSHA’s Occupational Exposure to Hazardous Chemicals in Laboratories (29 CFR 1910.1450) requires that every lab have a Chemical Hygiene Plan, which must include engineering controls (such as fume hoods) to minimize exposure to hazardous substances.

Many universities and research institutions take this one step further, explicitly requiring rotary evaporators to be operated in a functioning fume hood. These policies underline an important truth: proper containment is not optional when working with volatile solvents.

Rotary evaporator enclosures provide a dedicated, purpose-built way to meet these expectations, delivering the same core protection as a fume hood while overcoming many of its limitations.

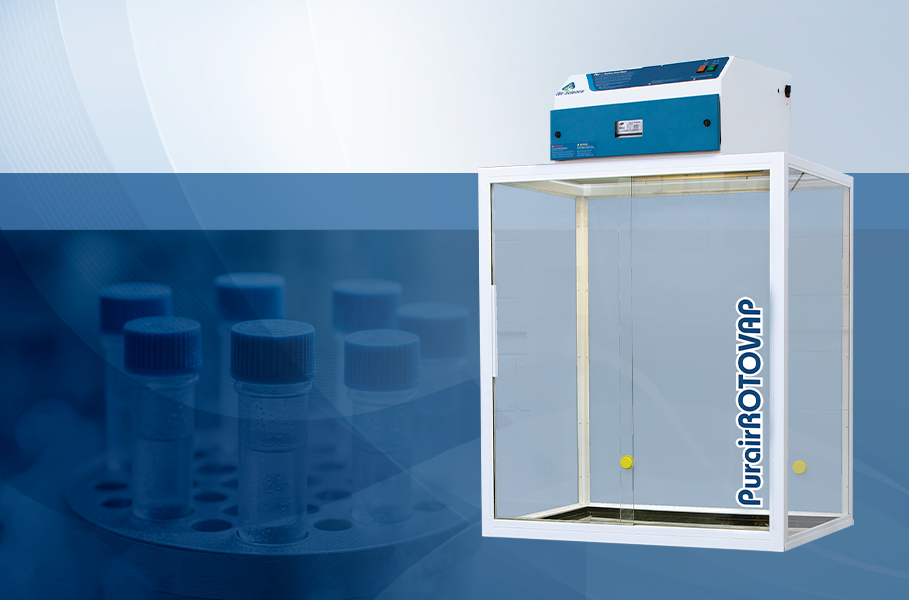

The Purair ROTOVAP Enclosure

Air Science® developed the Purair ROTOVAP enclosure with these needs in mind. Built from durable materials and available in ducted and ductless versions, the enclosure provides generous internal height, excellent visibility, and reliable containment. Its airflow system is designed to handle solvent vapors effectively, while integrated features such as filter monitoring and spill containment add layers of protection.

With the Purair ROTOVAP, labs gain a solution that keeps personnel safe, protects the work environment, and maintains compliance, all while making rotary evaporation more straightforward and manageable.

Conclusion

Rotary evaporators are indispensable in today’s laboratories, but their safe operation depends on more than careful technique. While fume hoods provide a baseline level of protection, they aren’t always designed for the unique demands of rotary evaporation. Purpose-built enclosures like the Purair ROTOVAP offer a smarter, safer, and more practical way to reduce risk while ensuring compliance with laboratory safety standards.

If your lab relies on rotary evaporation, it may be time to ask: Is a fume hood enough, or is it time to step up to a solution designed for the job?