Horizontal laminar flow hoods provide air streams that travel in the same direction (horizontally) and at the same speed with little to no turbulence. The goal of laminar flow is to eliminate swirls that can introduce particulate contamination to items on the work surface, resulting in uncontrolled results. Like other laminar flow cabinets, horizontal laminar flow cabinets are used in numerous fields to maintain a sterile work surface by preventing airborne particulates within the work zone.

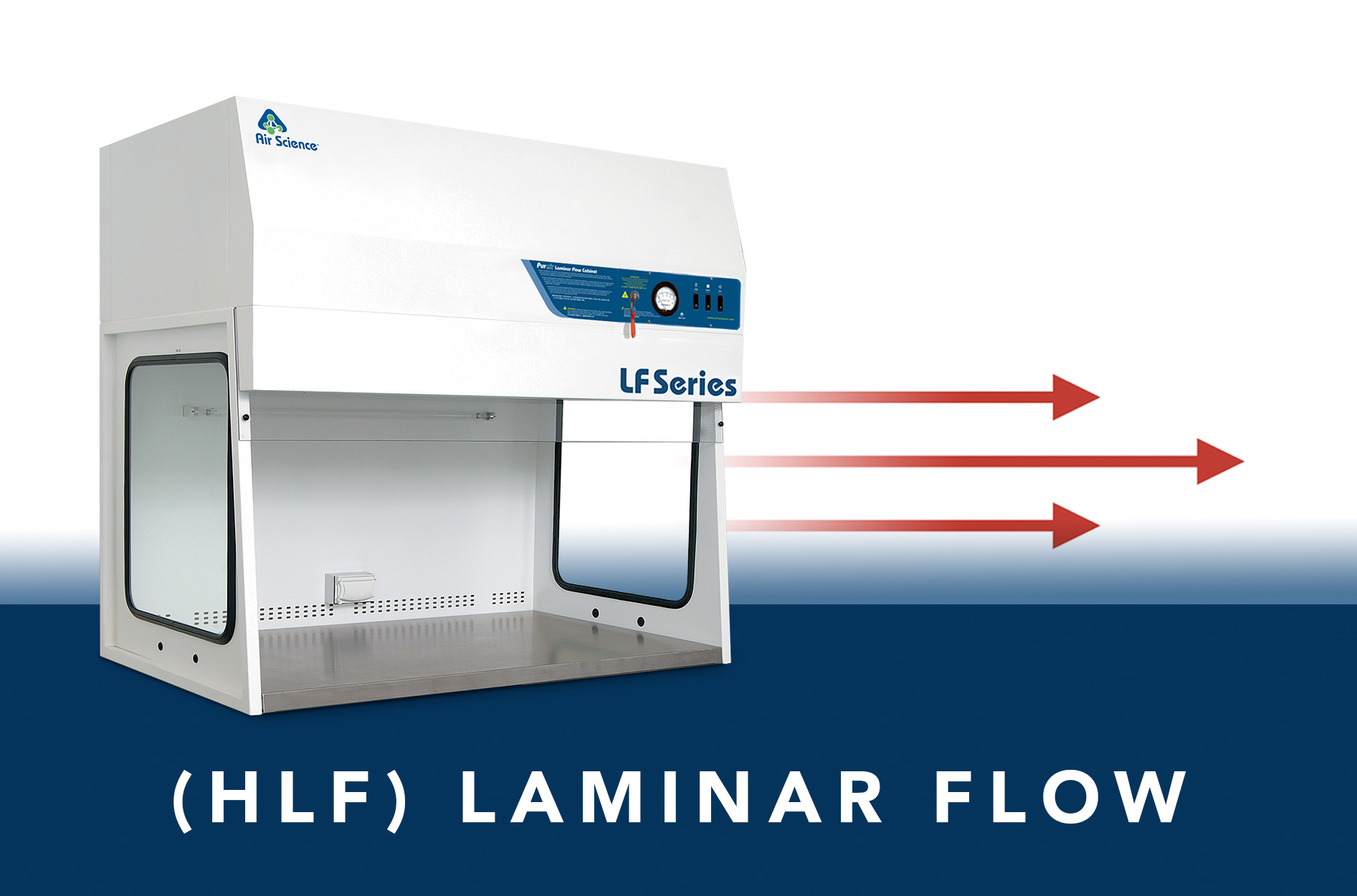

Horizontal laminar flow (HLF) workstations are typically used in applications that require less turbulence on the work surface and use mainly small pieces of equipment or utensils. In HLF hoods, room air is passed through a HEPA or HEPA/ULPA filter that is often located on the back wall. This filtered air is then passed horizontally from the rear of the unit straight across the work surface. The positive pressure streams of filtered air exhaust from the front of the cabinet. Using smaller tools on the work surface helps ensure that this air faces as little obstruction as possible to reduce possible turbulence. In a horizontal laminar flow hood, hands and gloves are typically positioned downstream of the sample, leading to greater contamination protection when compared to a vertical laminar flow hood.

Air Science offers both vertical and horizontal laminar flow hoods with easy-to-change filters, customizable options and personal sales advice throughout the decision process. Learn more about whether a horizontal laminar flow hood or a vertical laminar flow hood is right for you by downloading our free ebook, Horizontal Versus Vertical Laminar Flow.