We're Here to Help

239.489.0024

Contact Us

info@airscience.com

239.489.0024

info@airscience.com

Botanical and cannabis production manufacturing processes are highly regulated and require standardized laboratory practices to ensure high quality products. Botanicals which contain powerful natural antioxidants that scavenge free-radicals to protect the human body inside and out are said to do anything from improve digestion to minimize the risk of cancer. Care is taken during the manufacturing process to minimize personnel exposure to chemicals and botanical substances, while also protecting botanical and cannabis products from contamination.

Botanicals are substances obtained from a plant – in part or in whole – and used as additives in products within a large number of industries. Cannabis typically refers to the entire plant, stems, leaves, and seeds, as well as the botanical compound while the term marijuana historically excludes the plant stalks, oils, and other products used by the hemp industry.

Air Science manufactures laboratory products that are designed to protect operators, the environment, and the product during botanical and cannabis processing. Purair® Basic and Advanced Ductless fume hoods, the Purair BIO, and the Purair FLEX are all products that can assist botanical and cannabis manufacturers in certain steps of their process.

Learn more about the use and manufacture of cannabis and other botanicals in the US – Download our whitepaper “Cannabis and Botanical Products: Science, Regulation, and Quality Management.

Certain sterilization techniques used in the botanicals industry rely on various chemicals to sterilize, leach, and extract active ingredients from the plants. These processes can lead to personnel exposures that exceed defined safe exposure limits. Proper personal protective equipment, as well as purpose-designed safety barriers and equipment are necessary to ensure the safety of all personnel involved in the handling of raw materials and finished botanical products.

Ductless fume hoods are simple to install and can be purchased for almost any application. Ductless fume hoods are designed to capture harmful vapors on the work surface to protect operators from exposure. The contaminated air is then thoroughly filtered and clean air is released back into the laboratory or manufacturing environment.

Purair Basic and Advanced series ductless fume hoods are designed to protect the user and the environment from hazardous vapors that are generated on the work surface, such as those created by the cannabis or botanicals extraction process. Purair fume hoods use the Air Science Multiplex™ Filtration System, which filters out a wide range of chemical families with multistage, replaceable carbon filters.

Some botanical production procedures do not cause vapors, but do release particles of dust, plant biomass, and spores that may be detrimental to operators and the surrounding environment.

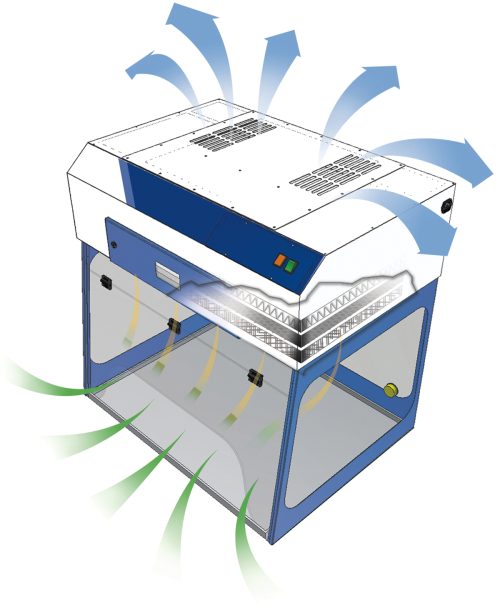

The Purair BIO Biological Safety Cabinet is a Class II Type A2 biosafety cabinet (BSC). The Purair BIO minimizes and contains Biosafety Level 1-3 agents, maintaining negative pressure inside the cabinet during operation to prevent contaminants from escaping the work area. HEPA filtration scours 70% of incoming room air to protect products, while the remaining 30% of exhausted air is filtered by a second HEPA filter.

Some botanicals manufacturing applications do not require additional airflow but do necessitate separation from the product or process for various reasons. Isolation chambers allow complete containment of the process and product within the chamber, effectively separating them from the operator and outside contaminants.

The Air Science Purair FLEX is a low cost, easily moved isolation chamber that can be used almost anywhere. The Purair FLEX is constructed of ArmorFlex® film which offers complete visual clarity and excellent solvent resistance across a range of chemicals.