Advanced Filtration Technology

Carbon & HEPA Filtration

Air Science® offers a range of competitively priced Filtco brand activated carbon filters, HEPA/ULPA replacement filters, and custom HEPA pleating services designed to ensure safety, efficiency, and adaptability across various applications.

Order replacement filters for Air Science and all major ductless hood brands and models through Filtco.com, our dedicated eCommerce site.

Filter Types

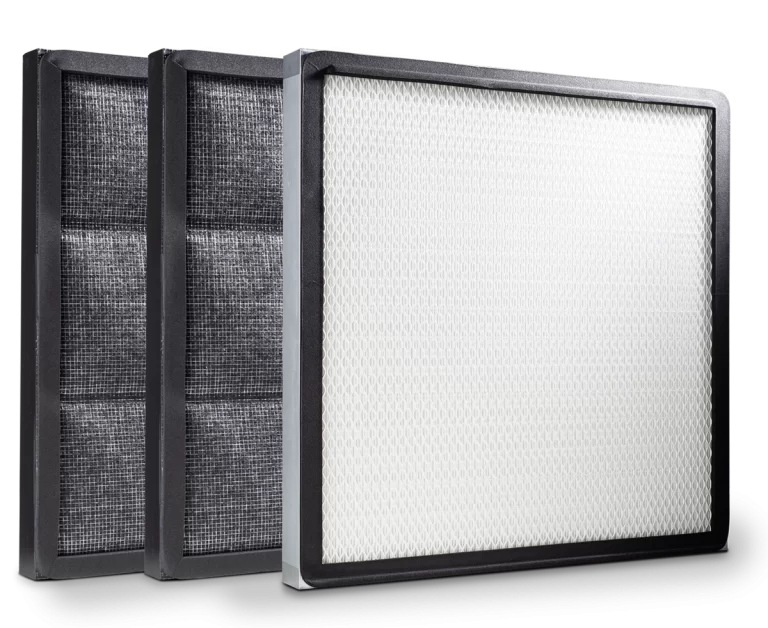

Carbon and HEPA Replacement Filters

We offer a variety of activated carbon filters, HEPA filters, and ULPA filters to fit most major ductless fume cabinet. Find your ductless laboratory equipment replacement filter by manufacturer below.

Pleating & Custom HEPA Filters

Filtco is a competitive supplier of custom HEPA/ULPA replacement filters. Our highly-experienced engineers can meet your unique filter and pleating needs regardless of your product. Contact us to get started.

Filter Technologies

Multiplex™ Filtration System consists of a pre-filter, main filter and optional safety filter to create a combination of chemical and physical architecture customized to each application.

Enhanced Filtration Technology™ (EFT), first introduced in 2010, is an innovation in ductless fume hood applications associated with activated carbon filtration and combinations with HEPA/ULPA filters.

Filtration Safety & Compliance

To ensure safe operation and properly maintain your ductless fume hood you must replace the filters on a regular basis and check your chemical handling and compliance with the requirements of current safety standards routinely.

Filtco Filters specializes in replacement carbon filters, high-performance HEPA/ULPA filters and maintenance supplies and services for Air Science® and all major ductless hood brands and models. All orders placed through Filtco Filters will be invoiced by Air Science. For a complete online directory and online ordering source, click here.

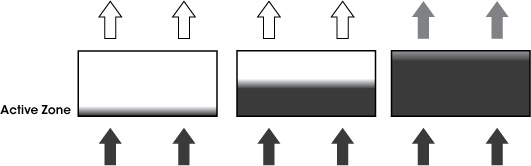

Activated Carbon Effectiveness

Ductless fume hoods provide cost benefits over ducted systems by eliminating the need for ductwork changes in the laboratory as well as utility savings. However, they are limited by the types and quantities of chemicals they can handle.

Before use, always confirm chemical compatibility and follow proper filter maintenance guidelines. See the Chemical Compatibility Form and Chemical Filtration Guide for details on chemical handling and filtration.

- Chemical Activation

- This technique is generally used for the activation of peat and wood-based raw materials.

- The raw material is impregnated with a strong dehydrating agent, typically phosphoric acid or zinc chloride mixed into a paste and then heated to temperatures of 500 – 800°C to activate the carbon.

- The resultant activated carbon is washed, dried and ground to powder.

- Steam Activation

- This technique s generally used for the activation of coal and coconut shell raw material which is usually processed in a carbonized form.

- Activation is carried out at temperatures of 800 – 1100°C in the presence of steam.

- Checking the airflow to ensure the pre-filter is not clogged with dust.

- Checking the exhaust air for chemical contaminants to ensure the main filter has not reached the breakthrough point.

WARNING

Failure to check chemical handling and failure to replace filters regularly can result in the recirculation of harmful vapors into the air.

CHEMICAL GUIDE

Use this guide to identify which ductless filtration solution is best suited for your chemicals and applications.

SafeSwitch HEPA Filter Shutter System is an optional bag-out contaminate containment system that enhances operator safety during HEPA filter changes.

Explore Related Resources

Need help? Call our support team at (239) 489-0024

Air Science® USA LLC is one of the industry’s leading international suppliers of fume filtration products to the medical, industrial, forensic and educational sectors.

Address

120 6th Street, Fort Myers, FL 33907

Contact Info

Phone: 239.489.0024

Email: info@airscience.com

©2025 Air Science® USA LLC. All Rights Reserved. Website designed and built by OffWhite.